In the welding process of chromium carbide wear resistant steel plate, welding stress is related to the change of the base plate strength. Wear plate itself is perpendicular to the welding bead during welding, and there is a consistent heat affecting to the base plate, the microstructure of the substrate has very small change, and can be considered as a whole, which is consistent.

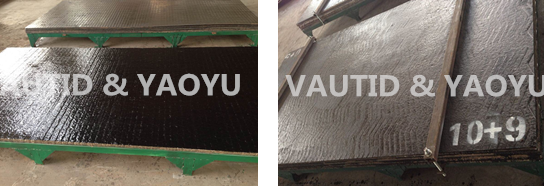

Welding beads will always go the width of overlay wear plate from us, and we have different welding pattern to meet your cutting and install requirements. Normally as you see, we need to consider material flow direction before we cut, it is severely limited the applications of normal pattern wear resistant plate, here in Zhangjiagang YaoYu, we newly designed weave pattern wear resistant overlay plate to break the limit, enables it much flexible to install either perpendicular or parallel to the material flow direction, make it more wear resistant than normal pattern wear plate, which increases service time of the overlay plate, bring great contributions to steel and cement industry, mining, quarry, dredging, thermal power etc.