Analysis of roller surface abrasive wear

1.Wear reasons

In order to improve hardfacing technology and the grinding efficiency, VAUTID-YAOYU wear resistant materials company made an analysis on roller surface abrasive wear. From the work principle of roller press, it is a normal phenomenon for roller surface abrasive wear during grinding process, and there are mainly 3 reasons for that:

(1)hardfacing materials are not suitable, wear resistance of roller surface itself is poor

(2)welding process is not reasonable, responds to a bad quality roller surface, causing peeling of roll surface

(3)material hardness is too high, poor grind-ability.

2.There is also a great wear difference if the roller press materials are different. And in general, raw material roller press wear fast than cement roller. The same model roller press will have a different roller surface wear degree due to different regions and different as raw materials.

3.We use different hardfacing materials for different grinding materials

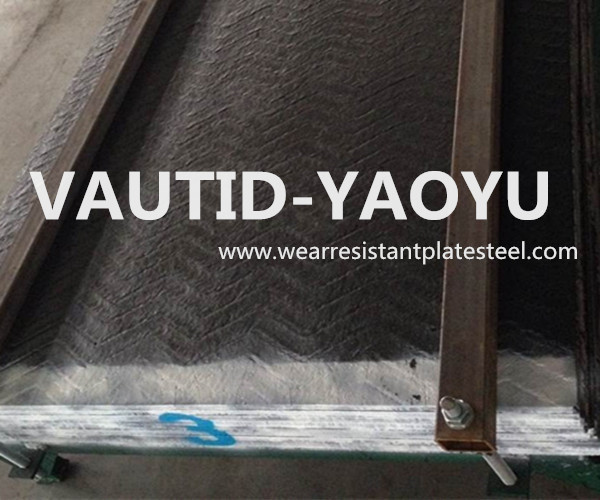

Different hardfacing materials corresponding to different grinding materials, the same one hardfacing material can not solve all the problems. VAUTID-YAOYU suggest the two main welding wires as below:

(1)VAUTID 100, VAUTID 100B is suitable for common cement grinding roller surface hardfacing

(2)VAUTID 143, VAUTID 145 is suitable for the raw material roller press roller surfacing

chromium carbide overlay plate made from VAUTID 100 is popular in cement industry, power plant, coal mining industry, against high abrasive wear.